Short Description:

Name:Hot Dipped Galvanized Steel Wire 12/16/18 Gauge Electro Galvanized Gi Iron Binding Wire for Building

Material: High quality low carbon steel

Processing and character: have been gone through the

process of wire drawing ,acid washing ,rust removig ,

annealing and coiling ,it offers excellet flexibilitu and softness.

Usage: used in weaving wire mesh,construction,handicrafts,

express way fencing mesh,packaging of products and other

daily uses.

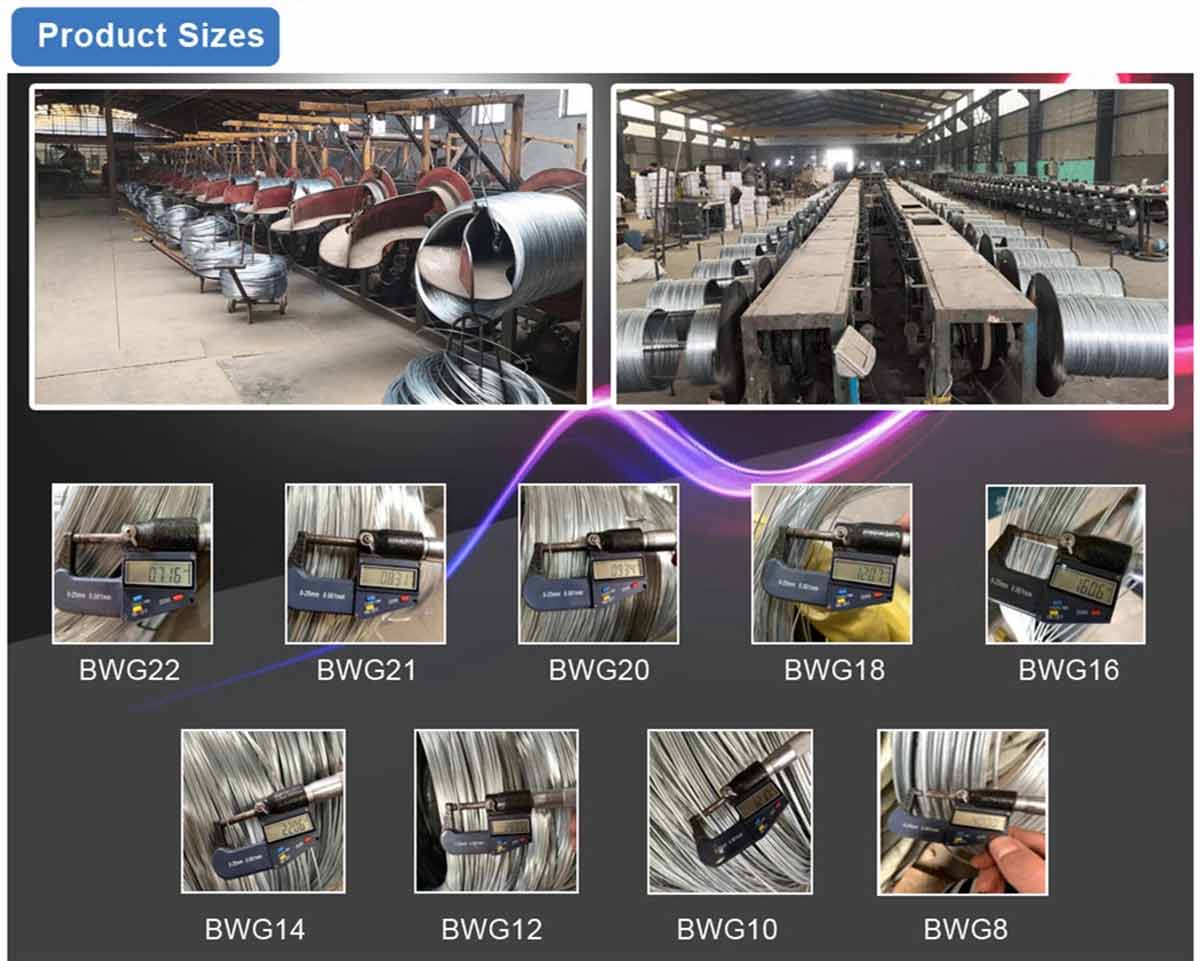

Specifucation: hot dipped galvanized iron wire,BWG8-BWG16;

electric galvanized iron wrie:BWG8-BWG36

| Material | high quality low carbon steel. |

| Processing And Character | Have been gone through the process of wire drawing, acid washing,rust removing, annealing and coiling, it offers excellent flexibility and softness. |

| Usage | Used in weaving wire mesh, construction, handicrafts, express way fencing mesh, packaging of products and other daily uses. |

| Specification | hot dipped galvanized iron wire: BWG24-BWG8; electric galvanized iron wire: BWG36-BWG8. |

1)Electro galvanized iron wire Electro galvanized iron wire is made with choice mild steel, through wire drawing, wire galvanizing and other processes.Electro galvanized iron wire has the characteristics of thick zinc coating, good corrosion resistance, firm zinc coating, etc.It’s mainly used in construction, express way fencing, binding of flowers and wire mesh weaving. Zinc coat: 10-18g/m2 Tensile strength: 350-550N/mm2 Elongation: 10% Galvanized Iron Wire is designed to prevent rusting and shiny silver in color. It is solid,durable and extremely versatile, it is widely used by landscapers, craft makers, building and constructions,ribbon manufacturers, jewelers and contractors.Its aversion to rust makes it extremely useful around the shipyard,in the backyard, etc.Galvanized wire is divided into hot dipped galvanized wire and cold galvanized wire (electro galvanized wire). Galvanized wire has good toughness and flexibility, the maximum amount of zinc can reach 350 g /sqm. With zinc coating thickness, corrosion resistance and other characteristics. 2)Hot-dip galvanized iron wire Hot dip galvanized iron wire is made with choice low carbon steel wire, through wire drawing, acid washing and rust removing, annealing and coiling. It’s mainly used in construction, handicrafts, woven wire mesh, express wayfencing mesh, packaging of products and other daily uses. Zinc coat: 45-180g/m2 Tensile strength: 350-550N/mm2 Elongation: 10% hot dipped galvanized steel iron wire 1.Surface Treatment of galvanized wire: Electro galvanized and hot dipped galvaized 2.Fearture of galvanized wire:galvanized steel wire for fencing wire with High tensile strength,small tolerance.Shiny surface, good corrosion prevention. 3.Application of galvanized wire:Gavanized steel wire being used for stranded conductors in overhead power circuitry, Cotton packaging, hanger,grape wire.binding wire, express way fencing as fencing wire, binding of flowers as wire ties in the garden and yard, and wire mesh making as weaving wires. 4.Remarks during use and handling: a. During transportation, handle softly and carefully, avoid bumping and damaging the steel wires. Moisture and rain prohibited. Steel wires must be stored in dry and well ventilated indoors b. Pay attention to the direction of steel wires when paying-off. Be sure the spools or coilis rotationg freely as to achieve identical tension of all the steel wires c. In case of batch usage, the remaining should be repacked to avoid oxidizing of the surface to guarantee coating.

Galvanized Iron Wire:

wire gauge size | SWG(mm) | BWG(mm) | metric(mm) |

8 | 4.06 | 4.19 | 4.00 |

9 | 3.66 | 3.76 | - |

10 | 3.25 | 3.40 | 3.50 |

11 | 2.95 | 3.05 | 3.00 |

12 | 2.64 | 2.77 | 2.80 |

13 | 2.34 | 2.41 | 2.50 |

14 | 2.03 | 2.11 | - |

15 | 1.83 | 1.83 | 1.80 |

16 | 1.63 | 1.65 | 1.65 |

17 | 1.42 | 1.47 | 1.40 |

18 | 1.22 | 1.25 | 1.20 |

19 | 1.02 | 1.07 | 1.00 |

20 | 0.91 | 0.89 | 0.90 |

21 | 0.81 | 0.813 | 0.80 |

22 | 0.71 | 0.711 | 0.70 |

Good flexibility : excellent toughness & elasticity, increasing 30% working efficiency easily use

New galvanizing process: uniform & firm zinc layer longer lifetime

Exact sufficient weight : on both unit pack weight & total container weight

Bright surface: clean & smooth suuface ,no rust,no crack

Adcanced production line: we have updated th production line on 2020 jan and improced the wire galvannzing process,it can reduce production cost a lot.Meanwhile the quality changes better a lot .

Surface brighter

Lifetime longer

Zinc layer more firm & uniform

1.Good galvanizing process ,smooth ,bright,chean

2.Good galvanizng equipment.uniform zinc layer ,no crack

3.Thick zinc coating,corrosiong resistance & durable strength

4.Twice annealing for enough long time,excellent touhness and elasticity